The Hlava STM delivers small-turbo response and big-turbo power…without wastegates or electronics.

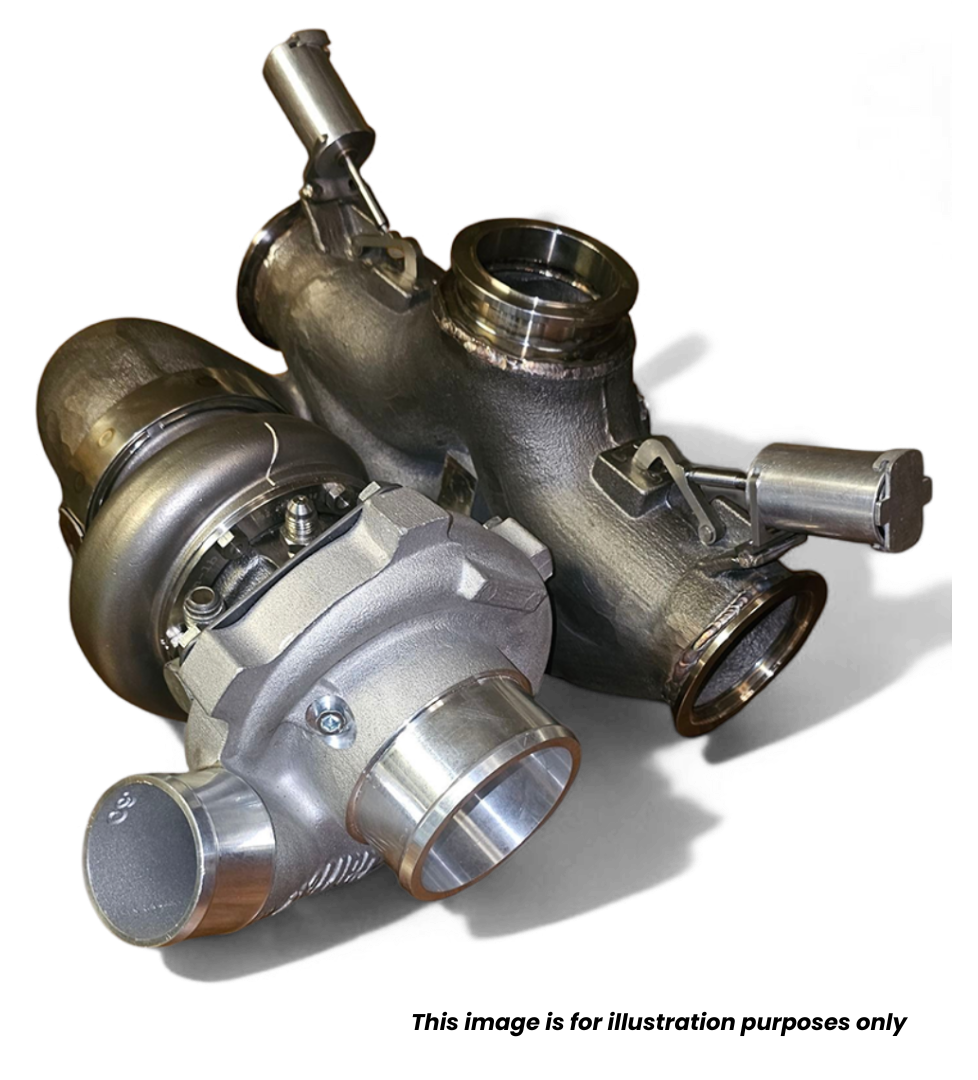

At low load, exhaust gas feeds the small (primary) turbocharger, providing near-instant spool. As exhaust gas exits the primary turbo, it’s channeled directly to the larger secondary turbocharger via a three-inch bridgepipe, priming it.

As pressure and volume rise, pre-primary turbo, intelligently engineered bypass valves open incrementally, directing all excess exhaust gas to the secondary turbocharger. When fully opened, they are “removed” from the exhaust flow path to the secondary turbo.

At elevated loads, you are receiving the horsepower your large secondary turbocharger was designed to provide in a highly efficient way, leading to low EMAP and intake air temperatures.

How STM applies them: The manifold’s bypass valves open incrementally as exhaust pressure and temperature rise. At full flow, the valves move completely out of the gas path, sending maximum energy to the large turbo, while keeping the small turbo primed for immediate response.

The Hlava STM operates using three fundamental gas laws: Boyle’s Law (pressure-volume relationships), Charles’ Law (temperature-volume relationships), and Gay-Lussac’s Law (pressure-temperature relationships). These laws optimize exhaust gas flow and energy extraction.

The dual inline full-flow bypass valves self-regulate exhaust flow between turbochargers based on the pressure, temperature, volume, and velocity of exhaust gas in the system, with spring tension in the valves’ actuators easily adjustable.

The Hlava STM is designed to allow the end-user to adapt whatever turbocharger combination is required for their engine build’s horsepower goals from their secondary turbocharger, while maintaining low-load turbocharger response from their primary turbocharger, making it truly universal for forced induction applications.

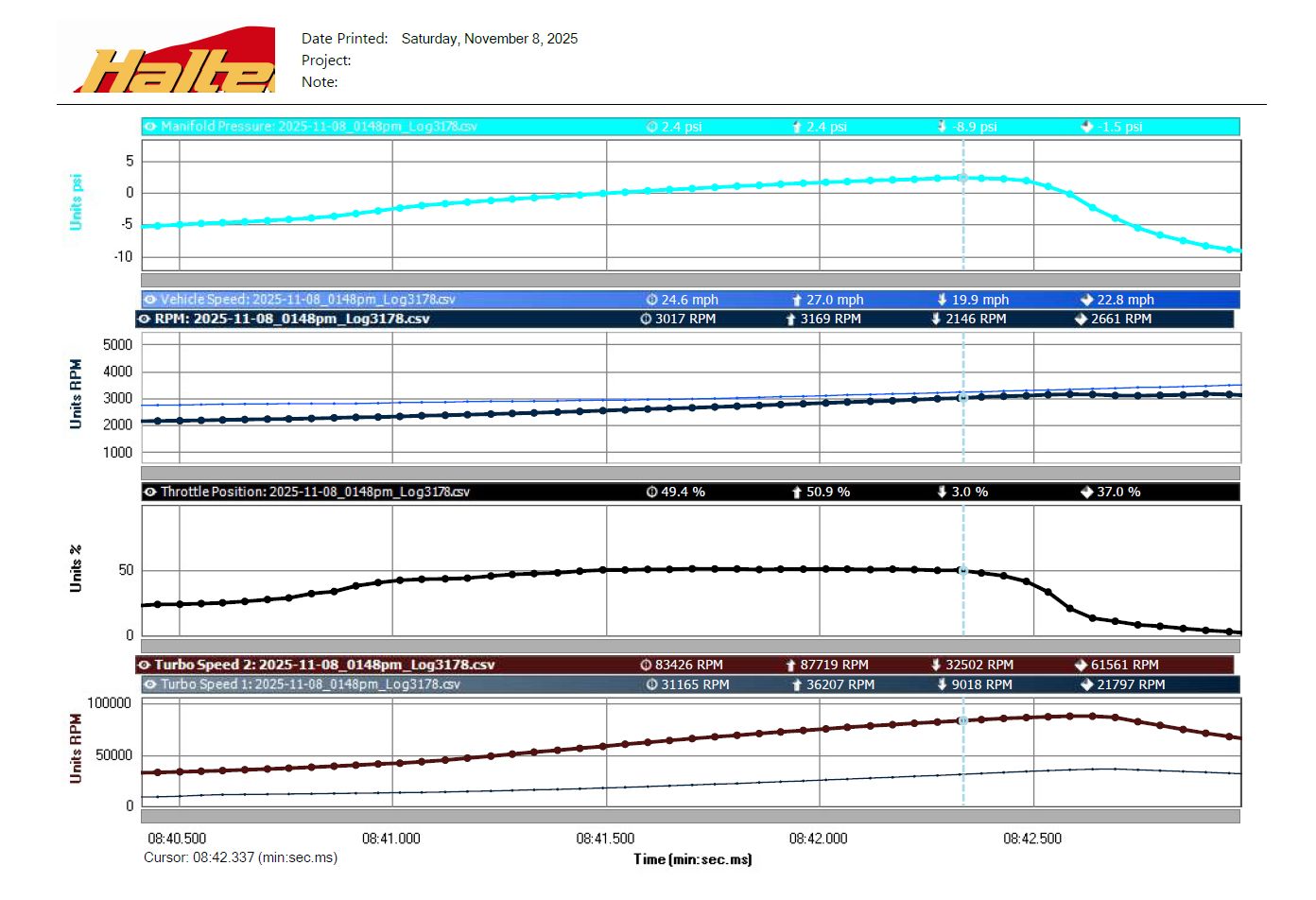

Snapshot Data of Gen II 2860 with .86 AR Housing Paired with G35-1050 with 1.21 AR Housing.

Turbo Lag is a thing of the past. 50% Throttle. Low Engine Speed. Low Vehicle Speed. and Still BOOST!

Snapshot Data of Gen II 2860 with .86 AR Housing Paired with G35-1050 with 1.21 Housing.

The transition point from Primary to Secondary Turbocharger.

Quicker spool, more fun, boost even at part-throttle. A unique build that turns heads.

New revenue opportunity. Install guides, tech support, and customer interest in proven sequential turbocharging.

Lower emissions, better fuel economy, lighter and simpler than superchargers. Applicable to all internal combustion engines designed for forced induction.

Since 2013, Andrew Hlava has been engineering a better way to deliver boost. The result is the patented Hlava STM — cast in Indiana, machined in Rockford, and protected by two U.S. patents.

U.S. Patent: 11,859,525

U.S. Patent: 12,228,069

Join the first wave of builds and see the results for yourself.

Join the first wave of builds and see the results for yourself.